Suspended pedals

- Easy cleaning of the cabin floor due to free space underneath the pedals

- Increased ease of use thanks to ergonomic pedal arrangement

- One-piece, removable doormat makes cleaning easier

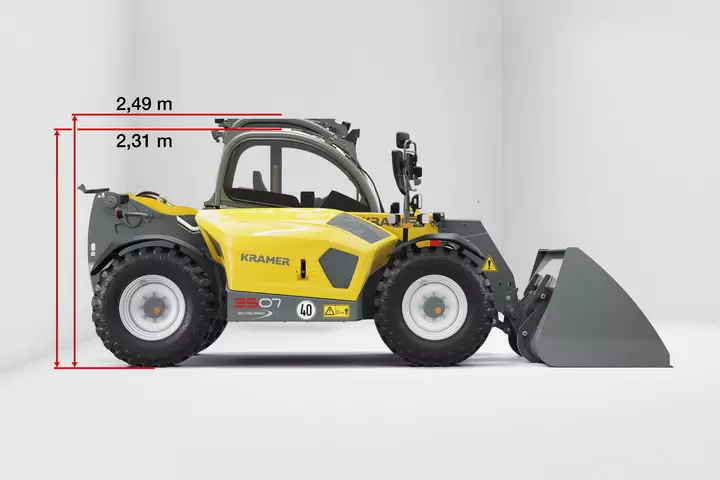

3507

The Kramer 3507 telescopic loader is the ideal telescopic loader for a wide range of applications. The telescopic handler has a compact design, low overall height and small turning radius. Despite its dimensions, it can be used in different ways thanks to the stacking height of 7.0 m and the 3.5 t payload. The 3507 telescopic handler's stepless travel drive up to a maximum of 40km/h, 140l/min load-sensing working hydraulics and intelligent driver assistance systems ensure maximum efficiency. In addition, the ergonomic and functional cabin ensures stress-free work.